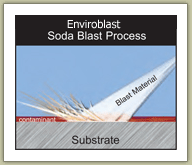

Soda Blasting is a revolutionary cleaning technology that propels bicarbonate of soda (Yes, everyday baking Soda - a non-toxic, non-hazardous food-grade material that is 100% water soluble) via compressed air onto the surface to be cleaned or stripped.

Soda blasting is a 100% non-abrasive, environmentally friendly way of removing paint, dirt, coatings, and any other surface contaminants without causing damage to the surfaces being cleaned.

Soda unlike its more aggressive rivals; sand, grit etc will not cause heat build up, sparks, or abrasion to the surface being cleaned.

How can Soda do this?

Biggest differentiator - Soda takes off anything on a surface but cannot remove anything within a surface!

For this reason, Soda:- cannot warp, bend or etch your metal panels,

- cannot pit your aluminium or glass,

- cannot tear up any of your rubber or plastic - just think, no more masking or stripping down!