Please see below a list of frequently asked questions. If you need to know more then feel free to contact us.

FAQ

-

Would Soda blasting work on graffiti removal?

Yes. When used with a little water Soda makes easy work of Graffiti removal. -

Can Soda remove Bitumen?

Until now, there has been no effective way to remove asphalt, tar or bitumen. Highly toxic chemicals were the only method known to date. Soda blasting quickly and easily removes and cleans difficult to remove substances including rubberised tar, spray sealers, underseal, surface treatments, epoxy resins, resurfacing concrete, bitumen and many more. -

Can I used Soda on fibreglass?

Soda blasting is the safest blasting media for fibreglass. Due to the softness of the media, you can remove levels of coatings down to your selected requirements (even to the gel coat without causing damage) and will leave you with a very smooth finish. You can see several photo examples of fibreglass on the applications/gallery page of our web site along with a video. -

Will there be any damage to my garden/plants?

Soda is alkaline so depending on the type of plant, soda can produce temporary discoloration or cause more serious damage. The most easily upset plants are flowering shrubs, such as roses, azaleas, or lilac. Trees and grass typically turn brown, and then recover in 4-6 months. Some plants are completely unaffected. The speed of any reaction with plant life can vary widely, depending on the type of plant. To avoid damage to plants from blasting with soda: avoid contact between plants and soda residue. Cover plants and prevent any liquid run-off from soaking the soil around plants. If contact is unavoidable, the customer should be aware that damage to plants could occur. To minimise damage: It is advisable to use a sprinkler for 4-6 hours to completely soak the soil, leaves, and branches before blasting. Continually rinse the leaves and prevent liquid run-off from soaking into the soil around the roots whilst blasting. After blasting, continue to soak the leaves and soil to thoroughly flush the soda away from the root structure. The amount of soaking after blasting depends on amount of residue in contact with leaves and roots. The goal is to reduce the sodium ion concentration below 0.5% vol. on the leaf surfaces and around the roots so that any damage will be minimised. -

What sort of area do I need for you to come to me?

Outdoor soda blast operations require a wide-open space and are not recommended in a regular residential area. The mobile compressor is an industrial diesel-powered unit and, with the blast gun, whilst blasting is loud. Soda is a soft, friable (crumbles easily) media and will blow in the breeze quite a distance. Typically, only a dusting of baking soda will remain on the ground with the rest being airborne. We must consider our neighbours (their homes, vegetation, cars etc.) and choose an outdoor area of least impact in which to blast. Soda blasting over a gravel area is generally best, but any area can be used. Staining of asphalt can occur due to baking soda's ability to remove grease and oils. Typical baking soda usage rates are around 25 Kgs per hour. Soda is water-soluble and will usually disappear after the next good rainfall. -

How quickly will it rust after Soda blasting?

Sand blasted ferrous metals require immediate coating to prevent rusting. By contrast, Soda Bicarbonate is a natural Rust Inhibitor. It will leave a coating on the metal that will inhibit rust for a long period of time. It is necessary to keep the project stored in a dry area. We have had cars go several months without any signs of rust; however, we do recommend that the project gets a primer coat as soon as possible. -

After Soda blasting how do I prep my vehicle for painting?

A thorough pressure washing is necessary to remove the soda residue before ANY coatings are applied. This is extremely important; WATER is the only way to remove the baking soda. Do not try to remove it any other way, it will not work and you may experience a coating failure. You MUST ensure that you have removed all Salts, Chlorides and Contaminants on the metal prior to priming. This is essential with any kind of media blasting; you MUST completely clean the bare metal prior to painting. -

Will Soda remove rust?

Due to the very nature of the process which is non-abrasive, Soda cannot remove rust from within your metal. If there are any loose rust patches on the surface, these can be removed. The rust will be cleaned, wholly exposed and left with a smooth finish ready for cutting out/treatment. -

How long does it take to strip a whole car?

That really depends on the size of the project, how many layers of paint, what kind of paint, how much body filler and whether it is all to be removed. Body filler can either be removed or left intact, depending on the customer's preference. Normally a medium sized car (i.e. Escort) exterior only, would take between 8 to 10 hours. A full Rotisserie project which could include the interior, the underneath, both sides of all panels, engine bay, boot etc. could take upwards of 18 hours. -

How much will it cost?

Enviroblast UK charge either by the hour or a job by job basis. Marine vessels and building projects are often charged by the size/square footage and may include some preparation and clean up time as all blast material is contained. There are many benefits of Soda blasting including, but not limited to the quality of surface finish that's ready for painting. The omission of any damage makes the operation cost effective in the majority of cases. -

Is Soda environmentally safe?

Yes. Soda itself has no impact on the environment and is completely safe. Otherwise known as baking soda, it is used in everyday cooking; this product is also used to settle your upset stomach. Its alkaline properties could harm plants and vegetation, all areas should be washed down with water after the cleaning process. -

Can Soda cause any damage?

No. If used correctly by a trained operator, it is unlikely that Soda Blasting will cause damage. As part of their training, operators are taught to evaluate the surface to be cleaned, as well as surrounding surfaces carefully and to blast a test patch if required. Soda blasting on a surface that is softer than the soda, i.e. some plastics, soft wood, leather, vinyl etc will cause scratching and surface removal. -

Is Soda safe on rubber and plastics?

Yes. With Enviroblast UK you can remove paint or other contaminants from surfaces next to these materials generally without a problem. -

Do I have to mask off glass or trim like sand blasting needs?

Rarely, in fact unlike sand which is abrasive; bicarbonate of soda does not harm windows, glass or the rubber seals around the area, however; it may be harmful to certain types of plastic trim, because you could be using 150 psi in some instances. You may, therefore want to remove or protect those possible areas. Other areas that may need protection are: wood, soft plastic, membranes and electric components. -

What about preparation, clean up and waste disposal?

Preparation is usually minimal as the soda causes no damage to the surrounding environment. It leaves very little residue as it disintegrates on impact. Masking or tenting is advised if there is sensitive equipment nearby. Disposal regulations should always be followed. Normally only the removed hazardous material needs to be disposed of as our Sodium bicarbonate has a pH of 8.3 and can be disposed of in most wastewater treatment systems. -

What about the small quantities of grease and oil on the surface?

The items to be cleaned should be as grease free as possible. Large amounts of grease or oil degrade and slow down the cleaning process. The media (soda) will not get stuck in the greasy corners, unlike bead / sand blasting. During the process of Soda blasting it converts the residues into a soap-like material through a process called saponification. -

Is Soda good at cleaning engines and greasy deposits?

Sodium bicarbonate breaks down hydrocarbons, which makes it an excellent method of de-coking and cleaning engine parts, or other areas where oil and grease are present. The Soda is then washed away leaving all of your components in working order. -

Is there any risk of fire when using Soda?

Soda is non-flammable, it can be used for cleaning in the petroleum industry and any environment where flammable gases or liquids may be present unlike other media which can cause sparks. -

Is there any heat build-up as with sand blasting?

There is no heat build up when blasting with soda and so the risk of warping is completely eliminated. -

When would you use sand over Soda?

In some manufacturing processes it is necessary to create a specific surface profile within your surface for the paint/treatment to adhere to. In this case, it is appropriate to sand blast the metal rather than Soda blast as Soda is incapable of achieving this. -

How does Soda Blasting Work?

The sodium bicarbonate used has a larger particle than the baking soda used in the food industry, although it is basically the same product and purity. These particles are then propelled by compressed air through our specialised blasting machines. The Soda particles remove surface contaminant by the energy released as the particles explode, when driven by the pressure, into contact with the contaminant surface. The resulting energy release disrupts the contaminant surface and blows it away, leaving the substrate completely unaffected. -

Will the process damage the items being cleaned?

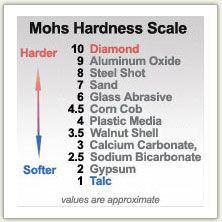

Unlike sand, grit, bead and glass blasting, which work by abrasion, Soda blasting works by shattering the soda crystals, and transferring energy to the coating, which then breaks off. Although this may sound dramatic, soda has the hardness just above talcum powder. On the Mohs Scale of Hardness of 1 to 10, diamond being 10 and talc being 1, soda is equal to a level 2.5 (see diagram). For objects or surfaces that may be considered delicate, we control the process by air pressure, soda levels and in some cases using a water/soda mix as required. Call us and discuss the requirements for your particular task.