We specialise in all forms of Blast Cleaning from hand tools to a block of flats using Abrasive and None Abrasive methods

Abrasive Blasting has moved on from the Sand Blasting days although most new blast media work in a similar way and the material used varies mainly in its coarseness. We use a wide variety of media to ensure we can use the best product for the specific job on iron, steel, stone & concrete. None Abrasive blasting works differently and is ideal for more delicate blasting of thin steel, aluminium, carbon, wood and fibreglass.

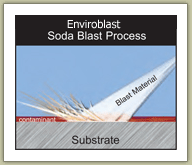

Non Abrasive Blasting we primarily use Soda Blasting, this is revolutionary non abrasive cleaning technology that propels bicarbonate of soda (Yes, everyday baking Soda - a non-toxic, non-hazardous food-grade material that is 100% water soluble) via compressed air onto the surface to be cleaned or stripped.

Soda blasting is a 100% non-abrasive, environmentally friendly way of removing paint, dirt, coatings, and any other surface contaminants without causing damage to the surfaces being cleaned.

Soda unlike its more aggressive rivals; glass, grit etc will not cause heat build up, sparks, or abrasion to the surface being cleaned and leaves a rust resistant residue providing protection prior to painting.

How can Soda do this?

Biggest differentiator - Soda takes off anything on a surface but cannot remove anything within a surface!

For this reason, Soda:- cannot warp, bend or etch your metal panels,

- cannot pit your aluminium or glass,

- cannot tear up any of your rubber or plastic - just think, no more masking or stripping down!